Range of Products

Our machines are configured specially on our customers’ requests.

You can find an overview of our product selection below.

Burnersystem

Patented Line-Gas-Burner Typ 40 S

This is an aluminum-burner consisting of only one part, which can be equipped with various burner strips, according to the required power.

To meet the increasing quality requirements, especially in the area of flame lamination, we paid special attention to a continuous flame temperature across the complete working width. During laboratory trials with the burner, a difference in temperature of less than 2 % at 1130 °C has been measured.

Additional advantages of the new burner compared to other burner types include:

Flame-Laminating-Plants

Flame-laminating-machine

Our plants can be combined on a modular construction basis, starting from the Bonding Unit which can be designed as a single or a sandwich laminating machine.

It is possible to install additional storage units for textile, foam, backlining and finished product for continuous operation or a tenter frame at any time.

The heart of the laminating machine – «Bonding» Laminating machine.

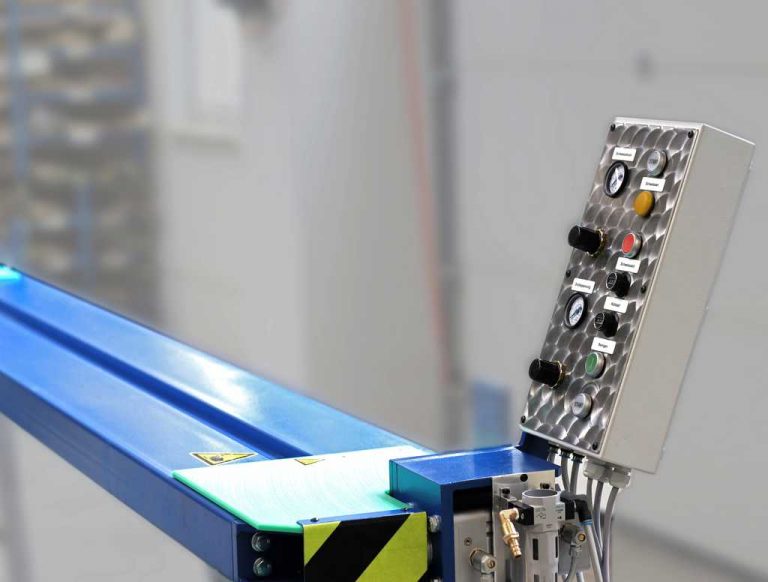

Our plants are equipped with state of the art safety-, control-and drive technology.

Control desk with control elements and operator-panel.

Working speed: up to 60m/min depending on material

Working width: up to 2000mm standard- special widths on request

Butt-Welding-Machine Type FSE

Butt-welding-machine Type FSE 20

For material thickness up to max. 20 mm (depending on its volumetric weight).

Type FSE 10

For material thickness up to max. 10 mm (depending on its volumetric weight).

Both versions available as „built on“ or mobile on rolls.

Gas Control Unit

Gas-air-mixing-device (single or double) for liquid gas or natural gas.

For operation of our Schmitt-Line-Gas-Burners.

Air inlet can be adjusted with an electrically adjustable fan.

Material Accumulators

Foam accumulator Type SWSP

Storage capacity: from approx. 50 to 70 m depending on height of accumulator.

Product accumulator Type FWSP

Storage capacity: from approx. 40 to 55 m depending on height of accumulator. Tension is adjustable.

Textile accumulator Type Z-Ski-Box

Storage capacity: about 50 m (depending on thickness of material) delivery with or without Butt-welding-machine possible.

Textile accumulator Typ L-SKi-Box

Storage capacity: about 50 m (depending on thickness of material) delivery with or without Butt-welding-machine possible.

Backlining accumulator Type SPUW

Storage capacity: approx. 50 – 100m (depending on thickness of material).

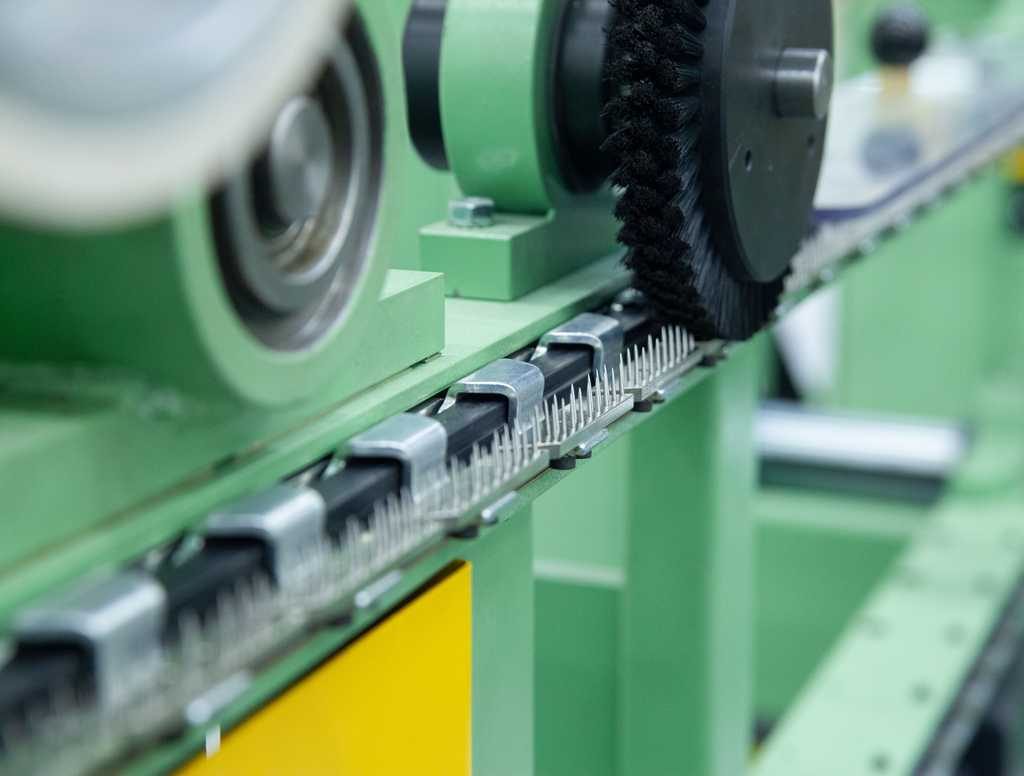

Perforating-Machines

Working width: 4800 mm

Tenter Frames

Tenter frame Type WFS

For the non-deforming transport of transverse elastic materials to our laminating machines, resp. textile or finishing machines.

Singeing Machine

For singeing and flaming of sheet materials (no pictures yet).

Winding Machine

With integrated butt-welding-machine. Constructed as conveyor-belt-machine for material rolls up to 2500 mm diameter.

Inspection Machine

Inspection machine Type BMK 2000

For inspection of woven and knitted fabrics, as well as laminated materials.

Winding Units

Our winding systems can be combined with web-tension-controls and winding-calculators for continuous winding-tensions across the entire winding-diameter.

Friction un- and rewinding unit for A-frames

Our winding systems can be combined with web-tension-controls and winding-calculators for continuous winding-tensions across the entire winding-diameter.

Foam unwinding

For foam bales of up to approx. 2500 mm in diameter.

Triple unwinding unit

For foam bales.

Double winding unit

For machines with continuous operation.

Center winding unit for A-frame un- and rewinding

Combinable with a tension control system for continuous winding tension across the whole diameter.